Space cooling is an integral part of maintaining comfortable indoor environments and supporting various industrial processes. Compressors are at the heart of chillers, playing a pivotal role in removing heat and enabling temperature control. When the refrigerant in a chiller absorbs heat, it transitions into a gaseous state, necessitating compression to release that accumulated heat. This article delves into the crucial components of chillers, exploring the various compressor types commonly used in commercial applications. We’ll provide an in-depth overview of three primary compressor types: reciprocating compressors, centrifugal compressors, and rotary-screw compressors.

The Role Of The Compressor

Compressors are the workhorses of cooling systems, particularly in commercial space cooling applications, where they often account for the highest electricity consumption. As such, selecting an appropriately sized and suitable compressor is paramount to achieve optimal system efficiency.

Reciprocating Compressors

Reciprocating compressors, often referred to as piston compressors, share a resemblance with a car engine cylinder. In these compressors, refrigerant, having absorbed heat and transformed into a gas, is drawn into the cylinder through suction valves. It is then compressed by a piston before being directed to the condenser. Reciprocating compressors can be categorized into two subtypes:

- Hermetically Sealed: In this configuration, the compressor and the motor are enclosed within a shared sealed housing.

- Open: These models have separate housings for the compressor and motor, typically offering higher efficiency, extended service life, and simpler maintenance requirements.

Reciprocating compressors are a cost-effective choice for cooling applications, providing design flexibility by allowing multiple units to serve varying cooling loads. Units can be activated or deactivated as required, offering a degree of capacity control.

However, these compressors have some limitations, including lower energy efficiency and demanding maintenance. When it comes to modulating the capacity of an individual unit, options are limited to ON/OFF control or cylinder unloading.

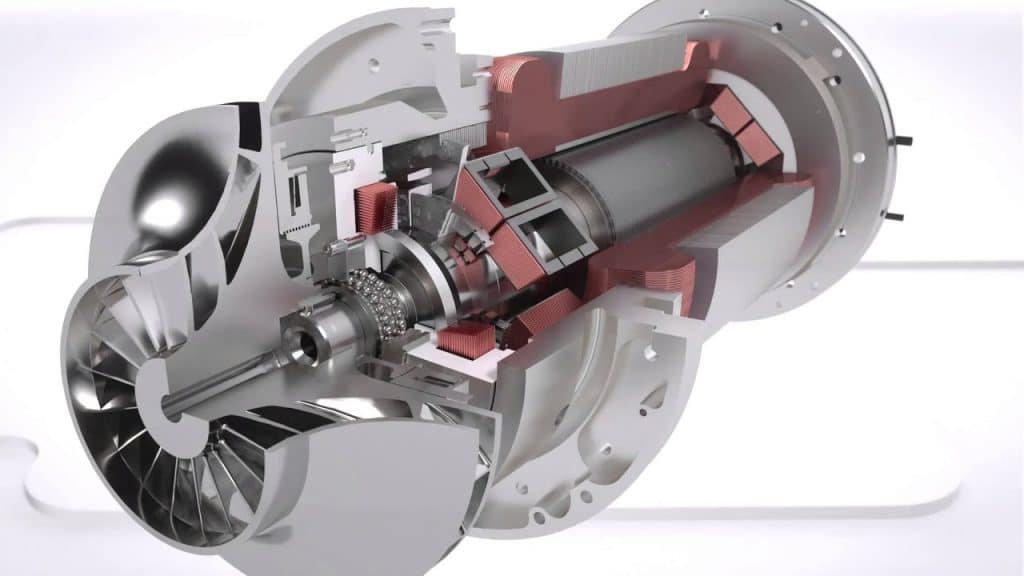

Centrifugal Compressors

Centrifugal compressors, akin to water pumps in design, employ an impeller to handle refrigerant. Similar to reciprocating compressors, they are available in both hermetic and open models, with the open construction often being more efficient.

At rated load, centrifugal compressors outshine reciprocating and rotary-screw compressors in terms of efficiency. They offer compact designs and cover a broad range of cooling capacities. Capacity control is usually achieved by manipulating inlet vanes to regulate the refrigerant flow into the impeller.

Nevertheless, centrifugal compressors exhibit a substantial loss of efficiency at part-load conditions and may be unable to operate at very low cooling loads due to surging – a phenomenon where already compressed refrigerant flows back into the impeller, disrupting its function. They have fewer moving parts than other compressor types, but the impeller is a highly specialized component that may necessitate factory orders in case of failure.

Rotary-Screw Compressors

Rotary-screw compressors employ two helical screws that mesh seamlessly while rotating at high speeds, creating a compression chamber. These compressors, like the other two types, are available in hermetic and open versions and employ a special valve for capacity control by varying the internal volume ratio.

While rotary-screw compressors may not be as efficient as centrifugal compressors at full load, they excel in part-load operation. Since building cooling loads vary throughout the year, rotary-screw compressors tend to have the lowest overall operating costs, making them an economically viable choice.

Their primary limitation is cost, making them most suitable when capacity control and part-load efficiency benefits can be realized. In cases where these advantages are less prominent, other compressor types may be considered.

Comparing Compressor Types

The following table presents a comparative analysis of the three main compressor types:

| Compressor Characteristics | Reciprocating | Centrifugal | Rotary-Screw |

|---|---|---|---|

| Initial Investment | Lowest | Intermediate | Highest |

| Energy Consumption (at full load) | Highest | Lowest | Intermediate |

| Part-Load Performance | Good | Poor | Best |

| Maintenance | Complex | Balanced | Low-demand |

The Choice Of Compressor For High-Rise Buildings

In the context of high-rise commercial buildings, such as those found in cities like New York, the selection of a space cooling chiller with a rotary-screw compressor is often the optimal choice. Despite being the costliest option, it offers superior performance when dealing with variable cooling loads, a common characteristic of tall structures. Furthermore, rotary-screw systems are known for their simplicity when it comes to maintenance, a crucial aspect in bustling commercial properties where disruptive downtime should be minimized.

Working with HVAC design engineers experienced in commercial systems ensures that your property benefits from a high-performance space cooling solution while maintaining energy efficiency. It’s crucial to consider not only the chiller type but also complementary systems like air handling units, hydronic piping, cooling towers, and HVAC controls. A well-rounded approach is key to achieving optimal indoor comfort and efficiency.

Conclusion

The choice of compressor in chillers plays a pivotal role in determining the efficiency and effectiveness of cooling systems. Reciprocating, centrifugal, and rotary-screw compressors each offer unique advantages and disadvantages. High-rise commercial buildings, like those in bustling urban centers, benefit from the reliability and efficiency of rotary-screw compressors, despite their higher upfront cost. Collaborating with experienced HVAC design professionals ensures that your space cooling system is tailored to your specific needs, delivering peak performance and energy efficiency. In the ever-evolving field of cooling technology, making the right choice for your space cooling needs can have a significant impact on both comfort and operational costs.

GIPHY App Key not set. Please check settings